NE Plate Chain Bucket Elevator

An NE Plate Chain Bucket Elevator is a continuous conveying machine that uses a plate chain as the traction component. Buckets are fixed at specific intervals on the chain, forming a closed-loop system driven by head and bottom sprockets. Material is fed into the buckets through the bottom inlet, vertically lifted, and discharged at the top outlet. Its fully enclosed structure effectively prevents dust from escaping, making it a clean and environmentally friendly choice for vertical transport.

Models & Specs

| Category | Item | Specification |

|---|---|---|

| Main Unit | Main Body Material | Carbon Steel |

| Material Thickness (mm) | Casing: 3.5 | |

| Total Equipment Height (mm) | 26,000 | |

| Bucket | Bucket Material | Carbon Steel |

| Bucket Volume (L) | 15 | |

| Bucket Dimensions (mm) | 400 × 200 × 300 | |

| Bucket Thickness (mm) | 3.0 | |

| Bucket Spacing (mm) | 305 | |

| Chain | Chain Material | 40Cr (Alloy Steel) |

| Sprocket | Sprocket Material | Carbon Steel |

| Inlet | Inlet Quantity (unit) | 1 |

| Outlet | Outlet Quantity (unit) | 1 |

| Drive System | Motor Type | Standard High-efficiency Motor |

| Reducer Model | ZSY200 | |

| Power (kW) | 18 kW | |

| Voltage & Frequency | 380V / 50 Hz | |

| Protection Grade | IP55 | |

| Installation Position | External drive; Motor and reducer are mounted at the top discharge end. | |

| Control Cabinet | Functions | Start, Stop, Emergency Stop, Jog |

| Note | Power cable not included | |

| Electrical Components Manufacturer | CHINT (ZhengTai) | |

| Bearing | Type | Sealed Bearing |

| Quick-open Access Door | Material | Carbon Steel |

| Location | Bottom | |

| Platform | Material | Carbon Steel |

| Operating Speed | 0.7 m/s | |

| Material Handled | Material Name | Dried Sand |

| Capacity (m³/h) | (To be determined / Not specified) |

Video

Details & Features

Our NE Series Bucket Elevator is engineered for performance, durability, and minimal maintenance. Here are the key benefits you can expect:

Superior Sealing & Environmental Protection

The entire machine features a fully enclosed structure. The casing connections are sealed with gaskets, creating a dust-tight system that prevents material leakage and dust emission. This not only protects the working environment but also ensures compliance with industrial environmental standards.

Robust & Reliable Construction for Longevity

Built to last, the core components are designed for maximum service life. The plate chain is forged from alloy steel and undergoes carburizing and quenching treatment, providing exceptional strength and wear resistance. The central casing is made from folded and reinforced steel plate (3.5mm thick), offering superior rigidity and resistance to deformation.

High Efficiency with Low Energy Consumption

Designed with energy savings in mind, the elevator operates with a high throughput while consuming less power. The advanced discharge principle and smooth material flow reduce energy waste. Coupled with low maintenance needs, this results in significantly lower overall operating costs.

How Does a NE Plate Chain Bucket Elevator Work?

The operation of the NE Bucket Elevator is straightforward yet highly effective, based on a continuous mechanical loop.

Return Journey: The empty buckets then travel back down the return side of the casing to the boot, ready to be reloaded, completing the cycle.

Loading (Inflow Feeding): Material is fed into the boot section of the elevator through the inlet. We offer two inlet angles: a 60° high inlet for moist or poor-flowing materials, and a 45° low inlet for dry, free-flowing materials. This strategic design ensures the buckets fill efficiently without spillage or backflow.

Vertical Lifting: The powerfully driven head sprocket pulls the plate chain with attached buckets vertically upward. The chain operates reliably under tension provided by a bottom counterweight with a screw tensioning device, which also helps prevent chain derailment.

Discharging (Gravity Induced Discharge): As the buckets pass over the head sprocket and change direction, the material is projected outward due to centrifugal force and gravity. It is then cleanly discharged through the outlet chute.

Example Configuration for Handling Dry Sand:

- Host: Carbon Steel

- Equipment Total Height (mm): 26000

- Bucket: Carbon Steel, 15L Volume, Size 400*200*300mm, 3.0mm Thickness

- Chain & Drive: 40Cr Chain, Carbon Steel Sprocket

- Drive Form: 18.5KW, 380V/50Hz, IP55 Motor with ZSY200 Reducer

- Inlet/Outlet: One Each (Low 45° Inlet for dry sand)

- Control: Control Cabinet with Start, Stop, E-stop, and Jog functions (Chint electric components)

- Additional Features: Quick-open inspection door at the bottom, Carbon steel platform, Sealed bearings.

Ideal Applications and Materials

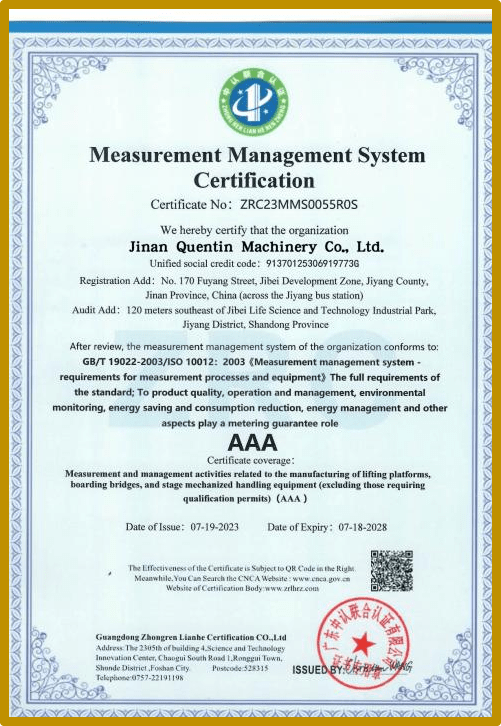

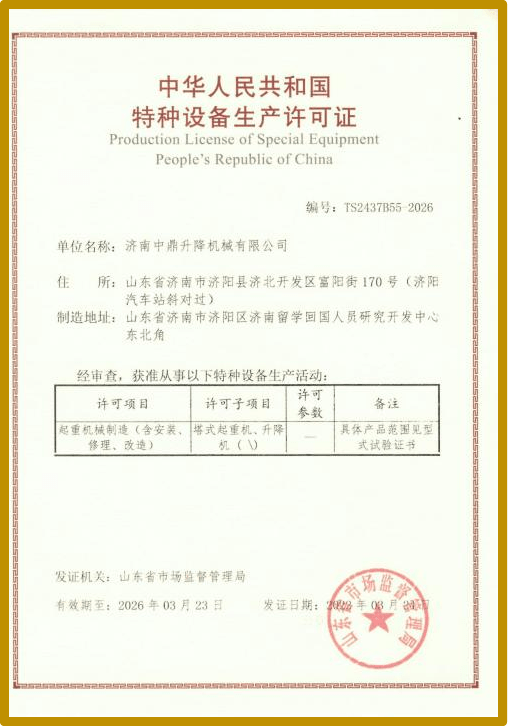

Why Choose Our NE Bucket Elevator?

When you invest in our NE Bucket Elevator, you get more than just a machine; you get a reliable partnership. We distinguish ourselves through:

- Proven Engineering: Our design incorporates industry-best practices for optimal performance and longevity.

- Premium Components: We use brand-name drives (e.g., ZSY reducers) and reliable electrical components (e.g., Chint) to ensure operational stability.

- Ease of Maintenance: The quick-open inspection doors and accessible platforms simplify routine checks and maintenance, reducing downtime.

- Custom Solutions: We offer tailored designs for specific material characteristics and spatial constraints.

Installation Services

1. On-site installation can be arranged in most parts of the world.

2. Remote installation guidance is available.

3. Installation videos and step-by-step instructions are provided.

4. Reliable installation team and professional installers.