26m Electric Telescopic Boom Lifts

G-J26Li Electric Telescopic Boom Lifts, offering a maximum working height of 28.8 meters. Perfect for high-rise construction, telecom maintenance, and industrial tasks, it features IP65 waterproofing for all-weather use. The electric powertrain ensures eco-friendly operation, while four-wheel drive and balanced axles provide superior traction and stability on any terrain. Enhance your efficiency and safety with the versatile G-J26Li.

Models & Specs

| Specifications | |

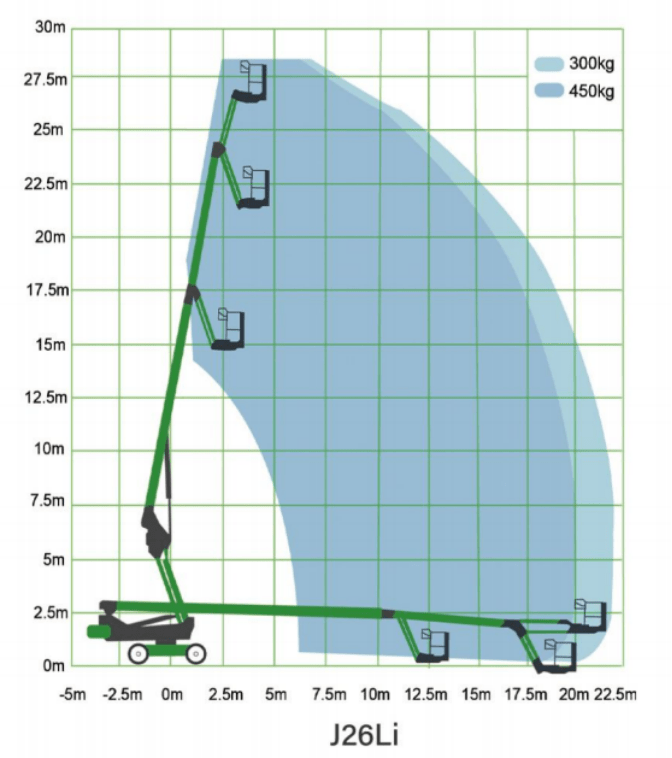

| Max. Working height | 28.8m |

| Max. Platform height | 26.8m |

| Max. Working radius | 22m |

| Platform Dimensions | 2.4*0.9m |

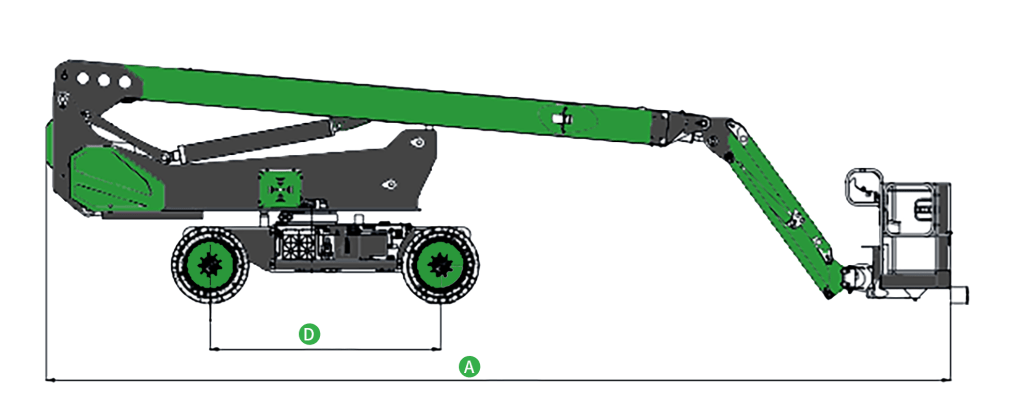

| Ⓐ Length(stowed) | 11.7m |

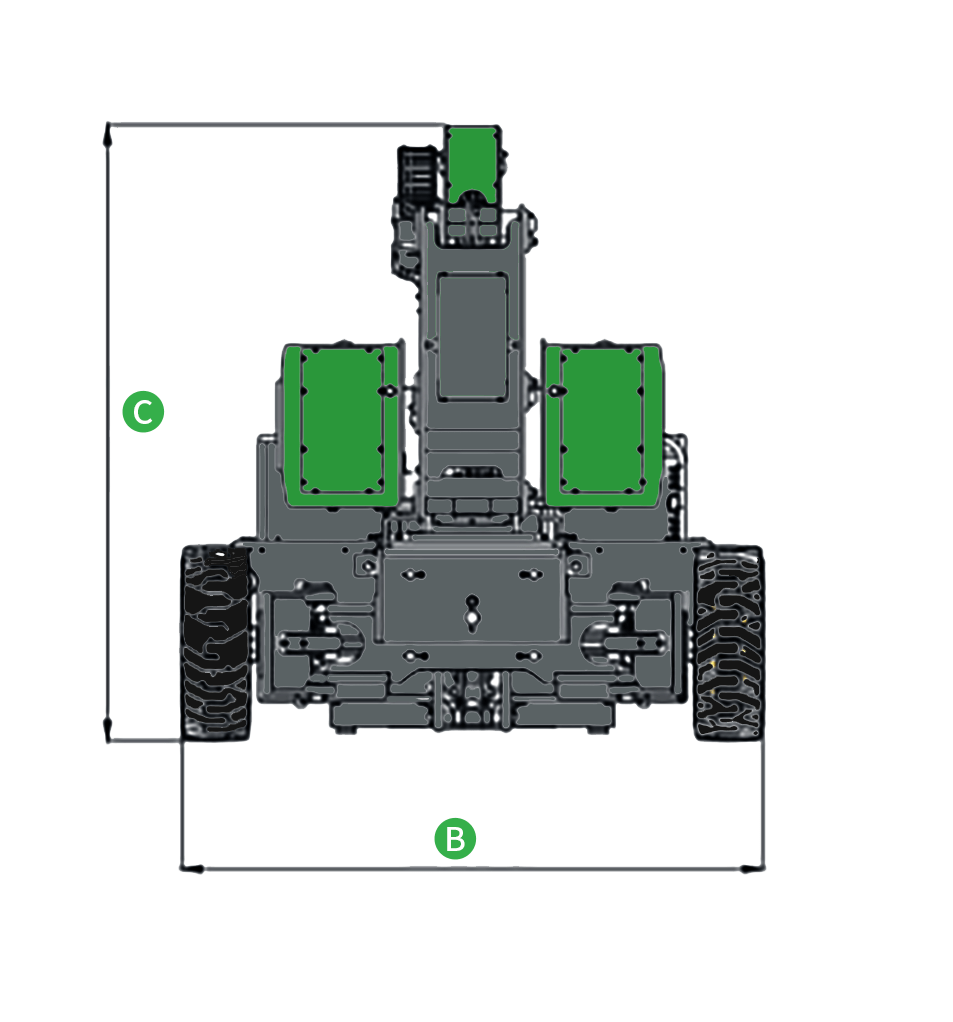

| Ⓑ Width(stowed) | 2.49m |

| Ⓒ Height(stowed) | 2.92m |

| Ⓓ Wheelbase | 3.2m |

| Ground clearance – center | 0.3m |

| Weight | 16600kg |

| Productivity | |

| Max. Lift capacity | 300kg/450kg |

| Number of platform occupants | 3 |

| Platform rotation | ±80° |

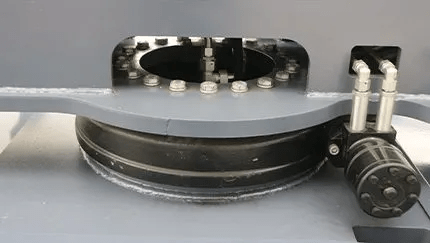

| Turntable rotation | 360° Continuous |

| Jib rotation (up/down) | ±70° |

| Drive speed – stowed | 5.5km/h |

| Gradeability – stowed | 45% |

| Max. Working angle (Tilt sensor activation) | 3° |

| Turning radius (outside) | 6.5m |

| Drive and steer mode | 4*2 |

| Power | |

| Battery | 80V/500Ah |

| Control voltage | 12V |

| Pump motor | 30kw |

| Drive motor | 5.2kw |

| Lithium Battery | Standard |

Features

The Bosch Rexroth platform control panel is equipped with proportional joystick controls and an emergency stop button.

The Bosch Rexroth ground control panel features an IP65 waterproof design and an emergency stop button.

The boom utilizes self-weight lowering technology and a load-sensitive hydraulic system to ensure smooth and energy-efficient operation.

The platform can automatically level itself within a ±80° rotation range.

The 360° continuous rotation of the turntable allows the platform to reach worksites with enhanced flexibility.

Advanced four-wheel AC drive technology combined with steering differential control significantly reduces tire wear and motor overload rates.

Equipped with solid tires, skid-proof and explosion-proof with longer lifetime, providing a stable and labor-saving operation.

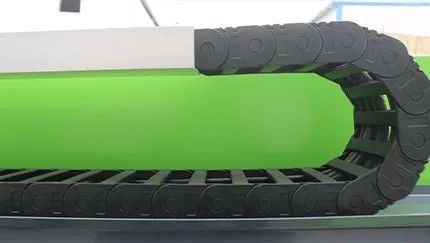

The international brand drag chain of the telescopic boom offers safety protection and guiding capabilities for the cables inside the booms.

Videos

Diagram

Other Boom Lifts

FAQ

Custom Options

Customize Your Lifts

Specifically sized, configured, mobile, high-cycle, or automated – when you need a lift to perform a specific function, we have the materials, components, and design techniques to produce a one-of-a-kind lifting solution for your application.

Lift Product Videos

Customized Cases

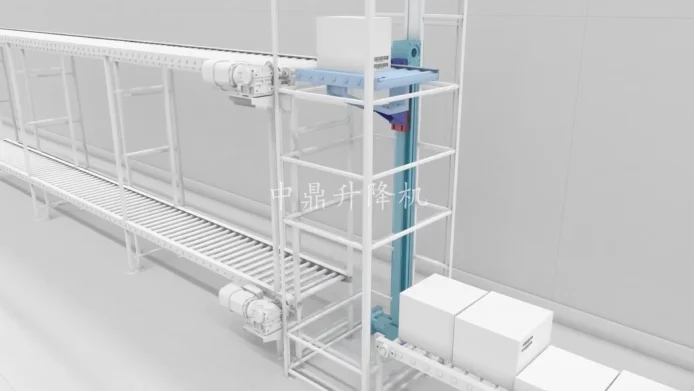

Modular Fork-Arm Continuous Vertical Lift | 2000 Units/Hour Vertical Conveyance | Multi-Material Sorting System

Stainless Steel Fork-Arm Continuous Vertical Conveyor | Clean Room Material Handling Solution

Stainless Steel Slat Chain Conveyor for Milk Powder | 304 Food-Grade Custom Solution

The SJD0.05-6 Reciprocating Lift For Food Industry Warehouses

Autonomous Vehicle Testing Calibration Rotating Platform

Scissor-Style 316L Stainless Steel Underwater Lifting Platform

Efficient and Stable Hydraulic Lift for Loading and Unloading Challenges in the Tobacco Industry

3-Ton Chain Flip Machine For Double Screw Pump

304 Stainless Steel Cargo Lift for Pharmaceutical Raw Material Handling

Reciprocating Lift Designed for Transporting Cat Litter

Efficient Vertical Reciprocating Lift: Tailored Solution for Bulk Transport in the Lithium Battery Industry

316 Stainless Steel Lift Platform: Automated Transport Solution for Breweries

| LIFT CAPACITY | |

|---|---|

| PLATFORM LENGTH | 1 – 3 m |

| PLATFORM WIDTH | ≤ 1 m |

| TRAVEL DISTANCE | > 11 m |