Hydraulic Roll Upender

Connected to the production line, 90 degrees, for transitioning cylindrical products

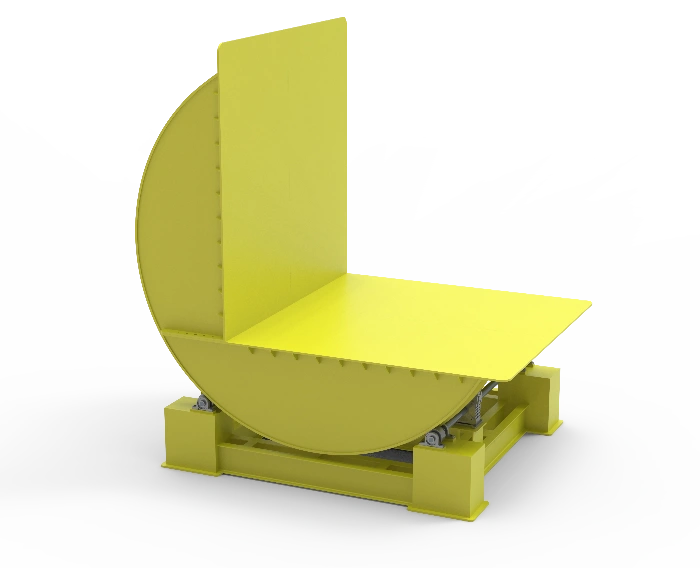

The tilting machine is connected to the production line and is designed for transitioning cylindrical products. When the round pipe reaches the transition station, the sensing switch detects the product and tilts it 90 degrees to position it upright.

Usage

The tilting machine is connected to the production line and is designed for transitioning cylindrical products. When the round pipe reaches the transition station, the sensing switch detects the product and tilts it 90 degrees to position it upright.

Models & Specs

| Product Model | FZPT-300 |

|---|---|

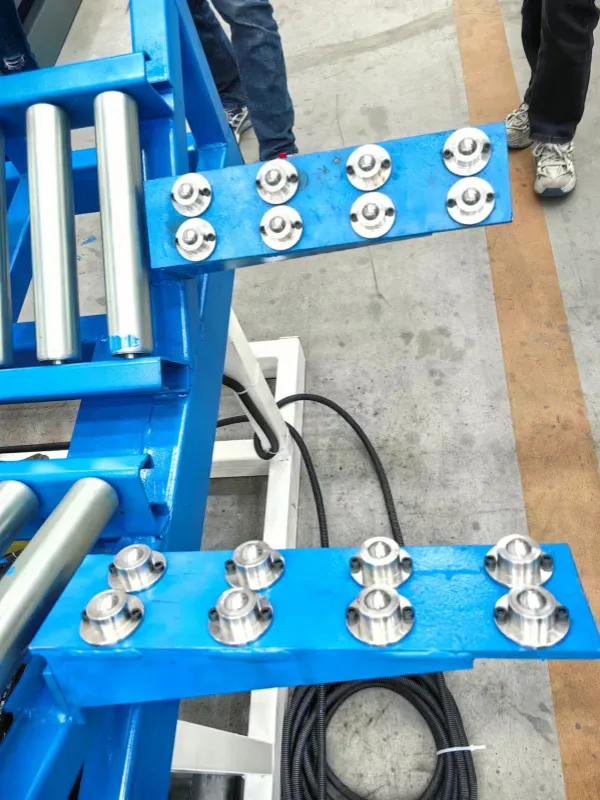

| Tilting Platform Size | 1500 * 1200 + 1200 * 1100 mm (one platform surface designed as a V-shaped powered roller conveyor, and the other surface designed with a comb structure) |

| Load Capacity | 300 kg |

| Tilting Angle | 90 degrees |

| Tilting Speed | Less than 60 seconds per cycle |

| Overall Coating | Medium gray or blue (can be customized according to user requirements) |

| Installation Method | Ground installation |

| Safety Devices | Emergency Stop: The equipment controller is equipped with an emergency stop button. In case of an emergency, pressing the button will immediately stop the operation, and it can be resumed by turning the button counterclockwise after the crisis is resolved. |

| Overload Protection: The hydraulic power unit is equipped with an overload relief valve. If the load weight exceeds the rated capacity, the hydraulic pump will cycle internally, preventing tilting. Once the load is reduced to the rated capacity, operation can resume. | |

| Explosion Protection: The cylinder has a built-in explosion-proof valve. If the hydraulic oil pipe accidentally disconnects or bursts, the valve will lock the hydraulic oil inside the cylinder, preventing the platform from falling due to sudden pressure loss. | |

| Missing Item Protection: The distribution box has a built-in missing item protection relay. If there is a missing item, the electric box enters a protection state, preventing power supply to the motor and protecting it from burning out. |

Custom Options

Specifically sized, configured, mobile, high-cycle, or automated – when you need a lift to perform a specific function, we have the materials, components, and design techniques to produce a one-of-a-kind lifting solution for your application.

Features & Benefits

Comprehensive Safety Features

Safety is prioritized with the inclusion of an emergency stop button that immediately halts operations in emergencies. This feature ensures a rapid response to potential hazards, protecting both operators and equipment.

Advanced Protection Systems

The FZPT-300 is equipped with overload, explosion, and missing item protection systems. These safeguards prevent damage during operation, ensuring the safety and longevity of both the machine and the products being handled.

Related Products Videos

| LIFT CAPACITY | |

|---|---|

| PLATFORM WIDTH | 1 – 2 m |

| PLATFORM LENGTH | 1 – 3 m |

| TRAVEL DISTANCE | 90° |