BRONNENCENTRUM > CASUSBEELDEN

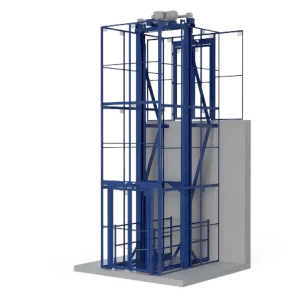

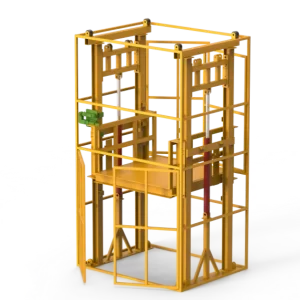

Goods Lift For Graphite Material Company

POSTED: 11/12/2024

Introduction

The customer is engaged in the research, production, and operation of graphite materials. To reduce the difficulty of loading goods onto trucks during the production process and improve overall efficiency, they use a lifting platform to adjust the height of the truck. This eliminates or minimizes the height difference between the goods and the truck bed, reducing the workload on forklifts and significantly shortening loading times.

Technical Solution

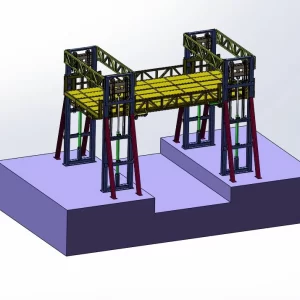

Structural Design: The solution adopts a single-layer four-span structure, with button controls for platform elevation. The platform automatically stops at both the highest and lowest limit positions.

Power System: The equipment features a 37 kW integrated pump station, utilizing a Siemens motor, Jinan Military Industry hydraulic pump, and Beijing Huade solenoid valve, ensuring reliable performance.

Electrical Specifications: The equipment operates on a power supply of 380V/3/50Hz, with a control voltage of DC 24V. Electrical components are from the Schneider brand, and the PLC is from Siemens.

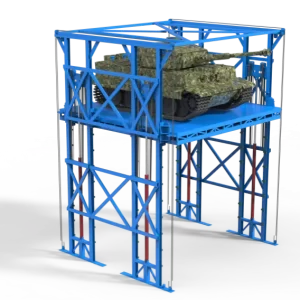

Safety Mechanism: The lifting platform is equipped with a fall protection device at high positions, ensuring that the platform height remains constant regardless of the load variations when vehicles enter or exit.

Synchronization Features: The equipment includes two synchronization rods that, along with the integrated rigid platform, ensure simultaneous lifting and lowering of the two-span scissor structure.

Emergency Descent Function: The platform is equipped with an emergency descent feature, allowing for manual control of the lift in situations where the electrical control system fails or during power outages.

Equipment Specifications

| Parameter | Details |

|---|---|

| Product Model | SJG60-1.75 |

| Platform Size | 23000 x 3300 mm |

| Required Space Size | 23100 x 3400 mm |

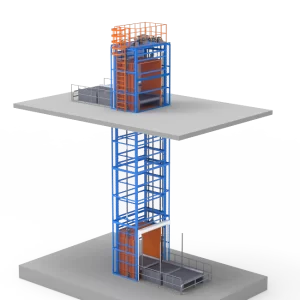

| Docking Stations | 2 |

| Structural Design | Single-layer four-span |

| Travel Height | > 1750 mm |

| Rated Load | > 60 tons |

| Lifting Speed | 1-2 m/min |

| Finish Color | Mid-gray or blue |

| Installation Method | Embedded foundation installation |

Safety Features

| Emergency Stop | The equipment controller has an emergency stop button. Pressing it halts operation immediately. To restore functionality, turn the button counterclockwise after the emergency is resolved. |

| Overload Protection | The hydraulic power unit is equipped with an overload relief valve. If the weight exceeds the rated load, the valve directs the hydraulic pump to internal circulation, preventing the platform from rising. Normal operation resumes once the load is within capacity. |

| Explosion Protection | The cylinder has an explosion-proof valve. If the hydraulic oil line disconnects or ruptures, the valve locks the oil inside, preventing sudden pressure loss that could cause platform descent. |

| Manual Descent | A built-in pressure relief valve in the hydraulic power unit allows the platform to descend by its own weight in case of power loss or failure. |

| Phase Loss Protection | The distribution box features a phase loss protection relay. In case of a phase loss, it enters a protective state, cutting power to the motor to prevent damage. |

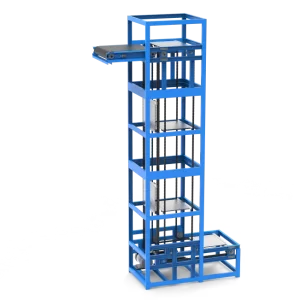

Related Freight Lift Products

Other Freight Lift Cases

If you want to customize your material handling equipment, please contact us.