Vertical Reciprocating Lifts

Home > Vertical Lifts > Vertical Reciprocating Lifts (VRC’s)

Product Catalog

OPLOSSINGEN PER TOEPASSING

WAT IS UW TOEPASSING?

Dankzij onze ontwerpbibliotheek en onze engineeringscapaciteiten kunnen we uw toepassingsuitdagingen aan. Wat uw uitdaging ook is, wij bouwen de perfecte lift die u nodig hebt.

OPLOSSINGEN PER INDUSTRIE

WAT IS UW BRANCHE?

Wij begrijpen branchespecifieke uitdagingen beter dan wie dan ook. Van lucht- en ruimtevaart tot detailhandel, wij zijn bij uitstek gekwalificeerd om al uw uitdagingen te begrijpen.

4 Berichten (1) Articulating Staircase (1) Automated (2) Automatisering (1) Batterij Elektrisch (2) Boomlift (4) Compact ontwerp (1) Diesel (1) Dubbele ketting (1) Duurzaamheid (2) Gemakkelijk te gebruiken (1) Efficient Actuation (1) Explosiebestendig (1) Snelle installatie (1) Vast (3) Geleiderail (3) Zwaar gebruik (3) Zeer sterk (4) Hydraulisch (20) Hydraulic Iris Opening (1) Industrial Elevators (1) inspect (2) Logistieke apparatuur (1) Logistieke oplossingen (1) Onderhoudsvriendelijk (1) MEZZANINE (1) Mobiel (1) Modulair ontwerp (2) Buitenlift (1) Production Line Solutions (1) Starre ketting (1) Rollenkettingen (2) Veiligheid (5) schaarlift (9) Zelfrijdend (3) Halfautomatisch (1) Klein (3) Roestvrij (1) Op rupsbanden (1) Getraceerd (1) Verticale lift (1) Verticaal transport (1) VRC (1) Warehouse Solutions (2) Weerbestendigheid (1)

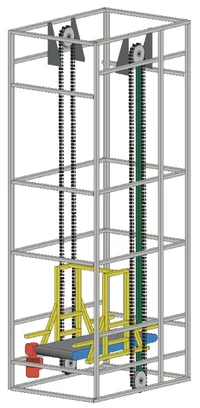

Verticale roterende liften (VRC's)

Vertical Reciprocating Conveyors (VRCs), also known as vertical lifts, are efficient for transporting materials to mezzanine floors. Unlike elevators, VRCs are not subject to strict elevator codes and regulations, as they are designed solely for moving materials and equipment—not passengers. This distinction allows for lower manufacturing and installation costs.

VRCs enhance safety compared to forklifts and other lifting methods, improving overall facility safety. For our VRC projects, Panel Built collaborates with dealers nationwide to provide customers with top-quality VRCs.

Toepassing

Materiaalverwerking

Perfect for transporting goods between different facility levels, our VRCs provide a reliable solution for moving heavy materials to mezzanines or upper floors.

Warehouse Operations

Our VRCs streamline the movement of pallets, boxes, and equipment within warehouses, optimizing space and increasing productivity.

Manufacturing Facilities

Ideal for transferring components and raw materials between production areas, our VRCs facilitate smooth workflows and help maintain operational efficiency.

Loading and Unloading

Designed to assist in loading and unloading trucks and containers, our VRCs reduce reliance on forklifts, enhancing safety and reducing operational costs.

Retail Environments

In multi-level retail spaces, our VRCs efficiently transport inventory from storage areas to sales floors, ensuring quick and organized restocking.

Food and Beverage Industry

Our VRCs are suitable for moving bulk materials and finished products in food processing and distribution centers, maintaining hygiene and safety standards.

Our Cases

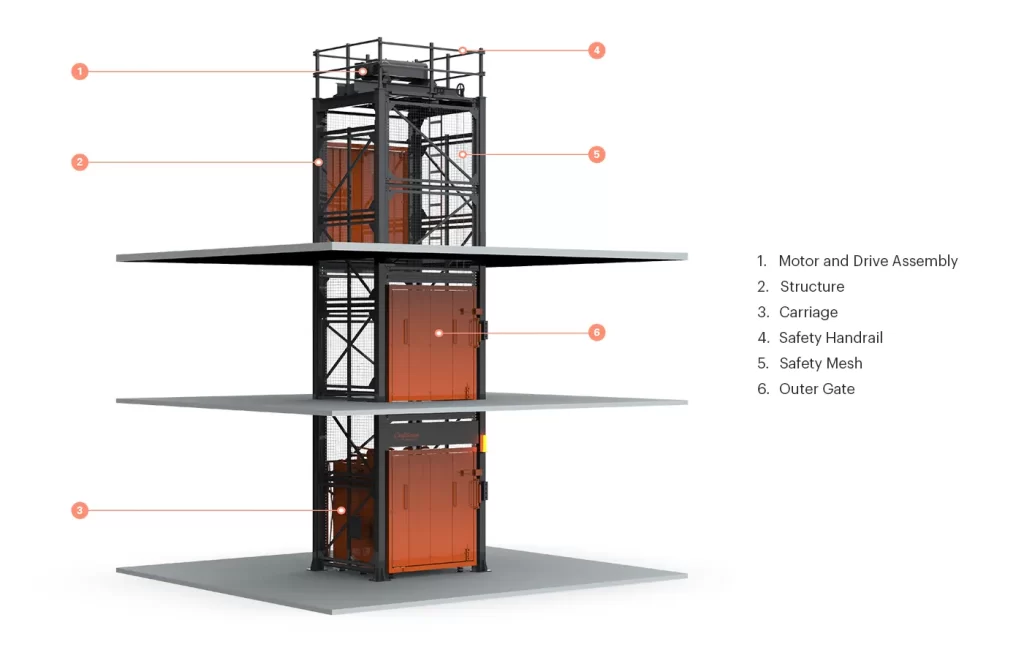

Key components

Drive System

Elektrische motor: Powers the lifting mechanism. Hydraulisch systeem: Used in some models for smooth and efficient lifting

Lifting Platform

The surface on which materials are placed. Designed for stability and durability.

Guide Rails

Structures that keep the conveyor belt aligned and prevent materials from falling off.

Control Panel

User interface for operating the VRC, allowing for control of the lift’s movement (up, down, stop).

Veiligheidsfuncties

Bescherming tegen overbelasting: Prevents lifting beyond the rated capacity.

Emergency Stop Button: Allows for immediate cessation of operation in case of emergencies.

Safety Locks: Engage when the platform is stationary to prevent accidental movement.

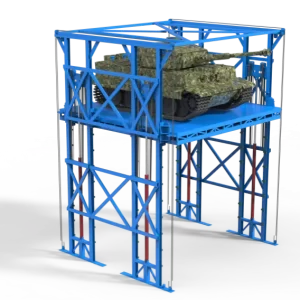

Support Structure

The framework that holds the entire system in place, ensuring stability and safety during operation.

Sensors

Detect the position of the platform and ensure safe operation by preventing collisions or over-travel.

Hydraulic Cylinders (if applicable)

Facilitate the lifting and lowering of the platform in hydraulic VRC models.

Top Rated Products

-

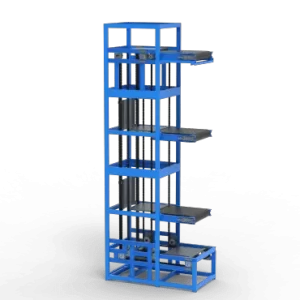

E-vormige verticale roterende transportbanden heffen

-

4-post Vrachtlift met volledige kooi

-

4 posten mezzanine goederenlift

-

2-palen wandklep Cargo Lift

-

8 Berichten Cargo Lift

Modellen en specificaties

| Model | E-vormige verticale roterende transportbanden heffen |

| Lifting Capacity | 500 lbs to 20,000 lbs (Customized) |

| Lift Speed | Standard travel speed is 20 fpm. Higher speeds available. |

| Load/Unload Patterns | “E” pattern |

| Levels | 1 to 6 stops (Customized) |

| Voeding | 230V/3P or 460V/3P |

| Toepassing | Moving heavy boxes, cargo, and pallets from one level to another. |