CONTINUOUS VERTICAL CONVEYORS

Home > Vertical Lifts > Continuous Vertical Conveyors

Product Catalog

OPLOSSINGEN PER TOEPASSING

WAT IS UW TOEPASSING?

Dankzij onze ontwerpbibliotheek en onze engineeringscapaciteiten kunnen we uw toepassingsuitdagingen aan. Wat uw uitdaging ook is, wij bouwen de perfecte lift die u nodig hebt.

OPLOSSINGEN PER INDUSTRIE

WAT IS UW BRANCHE?

Wij begrijpen branchespecifieke uitdagingen beter dan wie dan ook. Van lucht- en ruimtevaart tot detailhandel, wij zijn bij uitstek gekwalificeerd om al uw uitdagingen te begrijpen.

4 Berichten (1) Articulating Staircase (1) Automated (2) Automatisering (1) Batterij Elektrisch (2) Boomlift (4) Compact ontwerp (1) Diesel (1) Dubbele ketting (1) Duurzaamheid (2) Gemakkelijk te gebruiken (1) Efficient Actuation (1) Explosiebestendig (1) Snelle installatie (1) Vast (3) Geleiderail (3) Zwaar gebruik (3) Zeer sterk (4) Hydraulisch (20) Hydraulic Iris Opening (1) Industrial Elevators (1) inspect (2) Logistieke apparatuur (1) Logistieke oplossingen (1) Onderhoudsvriendelijk (1) MEZZANINE (1) Mobiel (1) Modulair ontwerp (2) Buitenlift (1) Production Line Solutions (1) Starre ketting (1) Rollenkettingen (2) Veiligheid (5) schaarlift (9) Zelfrijdend (3) Halfautomatisch (1) Klein (3) Roestvrij (1) Op rupsbanden (1) Getraceerd (1) Verticale lift (1) Verticaal transport (1) VRC (1) Warehouse Solutions (2) Weerbestendigheid (1)

Continuous Vertical Conveyors (CVC’s)

Vertical Reciprocating Conveyor (VRC) is a safe and economical way to lift and lower materials in factories, warehouses, distribution facilities, industrial plants, institutions, or anywhere products or supplies need to be moved from one level to another.

Toepassingen

Material lifts with vertical reciprocating conveyors provide rapid, efficient, and convenient access between mezzanines, balconies, basements, and multiple floors of buildings. They can be installed in building shafts, unused elevator shafts, or for internal/external applications.

Key components

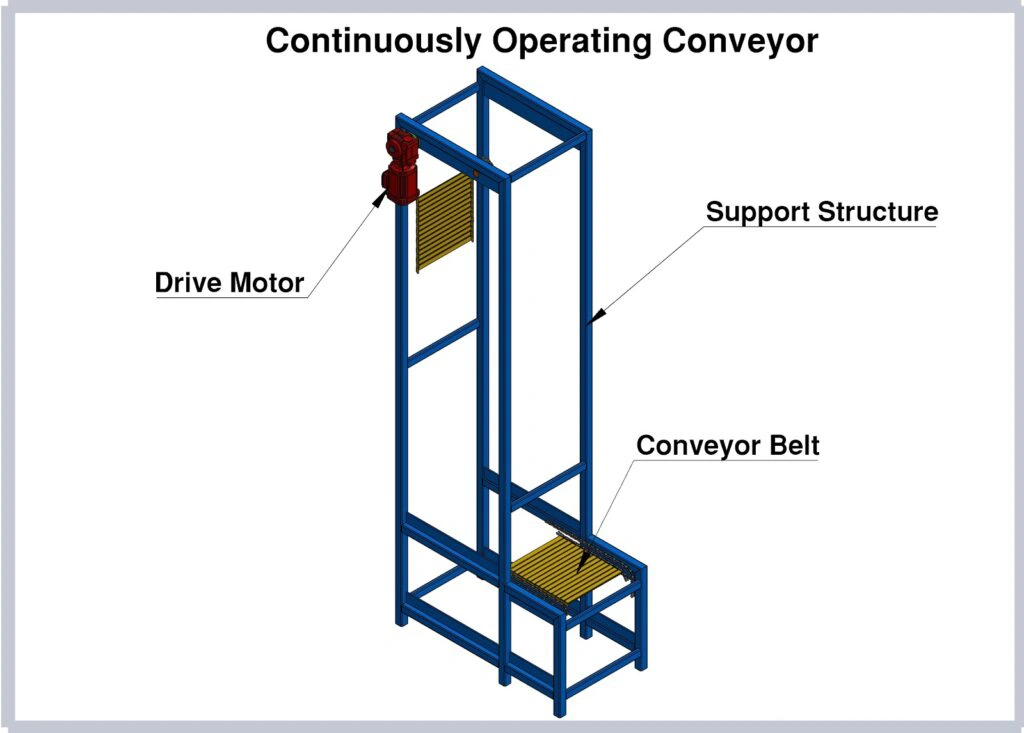

Conveyor Belt

The continuous surface that transports materials vertically, is designed for various load types.

Drive System

Includes motors and gearboxes that power the conveyor belt and control its movement.

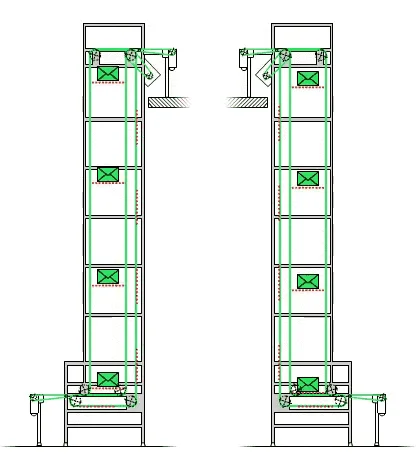

Guide Rails

Structures that keep the conveyor belt aligned and prevent materials from falling off.

Elevator Frame

The supporting structure houses all components and provides stability to the conveyor.

Cascading Discharge Mechanism

A system that allows for controlled unloading of materials at various heights.

Load Platforms

Areas where materials are loaded onto the conveyor and unloaded at the destination.

Safety Devices

Emergency stop buttons, guards, and sensors are included to ensure safe operation and protect workers.

Besturingssysteem

The interface for operating the conveyor allows for speed and direction adjustments.

Top Rated Products

-

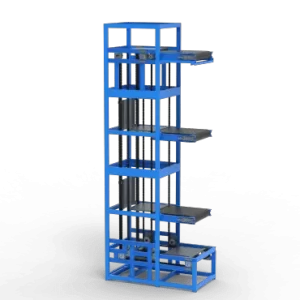

E-vormige verticale roterende transportbanden heffen

[LEES VERDER> 6 ton

5 - 7 m

W : 2 - 3 mL : 3 - 5 m -

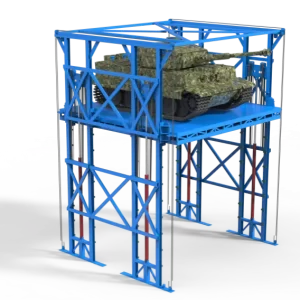

4-post Vrachtlift met volledige kooi

[LEES VERDER4 - 5 ton

7 - 9 m

W : 2 - 3 mL : 1 - 3 m -

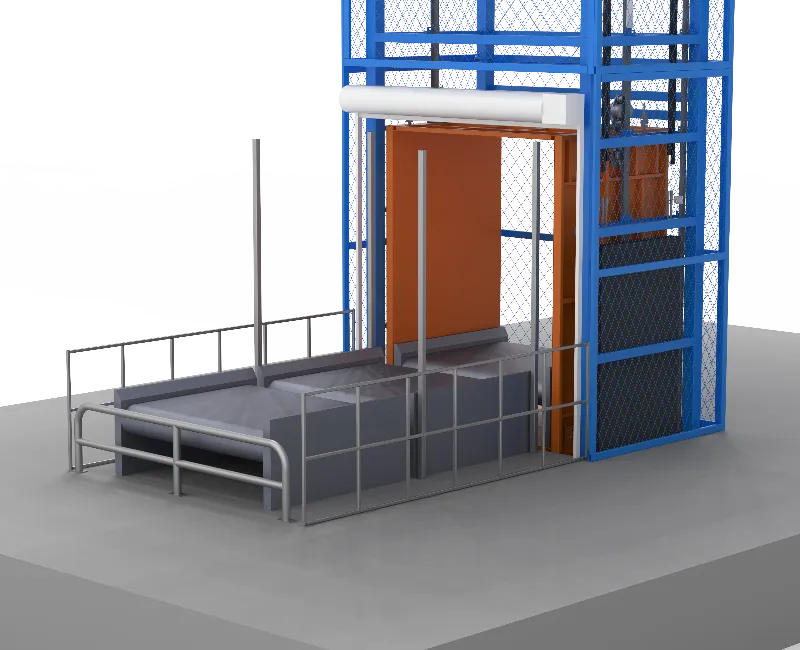

4 posten mezzanine goederenlift

[LEES VERDER4 - 5 ton

7 - 9 m

W : 2 - 3 mL : 1 - 3 m -

2-palen wandklep Cargo Lift

[LEES VERDER1 - 2 ton

7 - 9 m

W : 2 - 3 mL : 1 - 3 m -

8 Berichten Cargo Lift

[LEES VERDER> 6 ton

Aangepast

W : 2 - 3 mL : 5 - 7 m