How often should scissor lifts be inspected

Home > Schaarlift > How often should scissor lifts be inspected

FAQ

Tags

4 Berichten (1) Articulating Staircase (1) Automated (2) Automatisering (1) Batterij Elektrisch (2) Boomlift (4) Compact ontwerp (1) Diesel (1) Dubbele ketting (1) Duurzaamheid (2) Gemakkelijk te gebruiken (1) Efficient Actuation (1) Explosiebestendig (1) Snelle installatie (1) Vast (3) Geleiderail (3) Zwaar gebruik (3) Zeer sterk (4) Hydraulisch (20) Hydraulic Iris Opening (1) Industrial Elevators (1) inspect (2) Logistieke apparatuur (1) Logistieke oplossingen (1) Onderhoudsvriendelijk (1) MEZZANINE (1) Mobiel (1) Modulair ontwerp (2) Buitenlift (1) Production Line Solutions (1) Starre ketting (1) Rollenkettingen (2) Veiligheid (5) schaarlift (9) Zelfrijdend (3) Halfautomatisch (1) Klein (3) Roestvrij (1) Op rupsbanden (1) Getraceerd (1) Verticale lift (1) Verticaal transport (1) VRC (1) Warehouse Solutions (2) Weerbestendigheid (1)

Hoe vaak moeten schaarliften worden geïnspecteerd?

Scissor lifts are essential tools in various industries, providing safe access to elevated work areas. However, to ensure their continued safety and functionality, regular inspections are crucial. But how often should these inspections occur?

Daily Inspections

Most manufacturers recommend that scissor lifts undergo a daily inspection before use. This pre-use check typically involves examining the lift’s overall condition, including:

- Hydraulic Systems: Check for leaks and proper fluid levels.

- Veiligheidsfuncties: Ensure that guardrails, emergency stops, and safety alarms are functional.

- Tires and Brakes: Inspect for wear and proper inflation.

- Besturingselementen: Test all controls to ensure they operate smoothly.

Conducting these daily checks helps identify potential issues before they lead to accidents.

Monthly Inspections

In addition to daily checks, a more thorough inspection should be performed monthly. This inspection might include:

- Structural Integrity: Look for signs of wear, corrosion, or damage.

- Electrical Systems: Inspect wiring and connections for signs of wear or damage.

- Battery Maintenance: Check battery levels and terminals for corrosion.

Monthly inspections help ensure that the lift remains in safe working order and can aid in extending the equipment’s lifespan.

Annual Inspections

Beyond daily and monthly checks, comprehensive annual inspections by a qualified technician are essential. These inspections often include:

- Load Testing: Verifying the lift can handle its rated capacity.

- Detailed Safety Checks: Involving a thorough examination of all systems, components, and safety features.

- Compliance Verification: Ensuring the lift meets all relevant safety regulations and standards.

Annual inspections are vital for maintaining compliance with OSHA and other safety regulations, ensuring both operator safety and legal adherence.

Conclusion

In summary, scissor lifts should undergo daily inspections before each use, monthly inspections for a more in-depth review, and annual inspections conducted by qualified professionals. Regular maintenance and inspections not only ensure the safety of operators but also prolong the life of the equipment. By adhering to these guidelines, businesses can minimize risks and maintain a safe working environment.

Top Rated Products

-

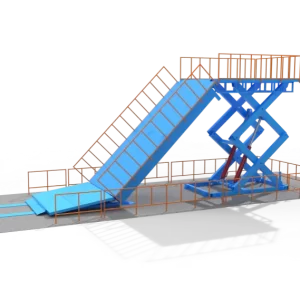

Laadklep met schaarlift

[LEES VERDER2 - 3 ton

30˚ - 45˚

W : > 6 mL : > 11 m -

G-GTJZ16RT 16-meter Diesel Schaarhoogwerker

[LEES VERDER≤ 1 ton

> 11 m

W : 1 - 2 mL : 3 - 5 m -

G-GTJZ13RT 13-meter Diesel Schaarhoogwerker

[LEES VERDER≤ 1 ton

> 11 m

W : 1 - 2 mL : 3 - 5 m -

G-GTJZ10RT 10-meter schaarlift diesel

[LEES VERDER≤ 1 ton

9 - 11 m

W : 1 - 2 mL : 3 - 5 m -

CFPT1214LD 10m schaarlift met rupsbanden

[LEES VERDER≤ 1 ton

9 - 11 m

W : 1 - 2 mL : 1 - 3 m

Contact with our experts, or request a quote now.