FORRÁSKÖZPONT > ESETTANULMÁNYOK

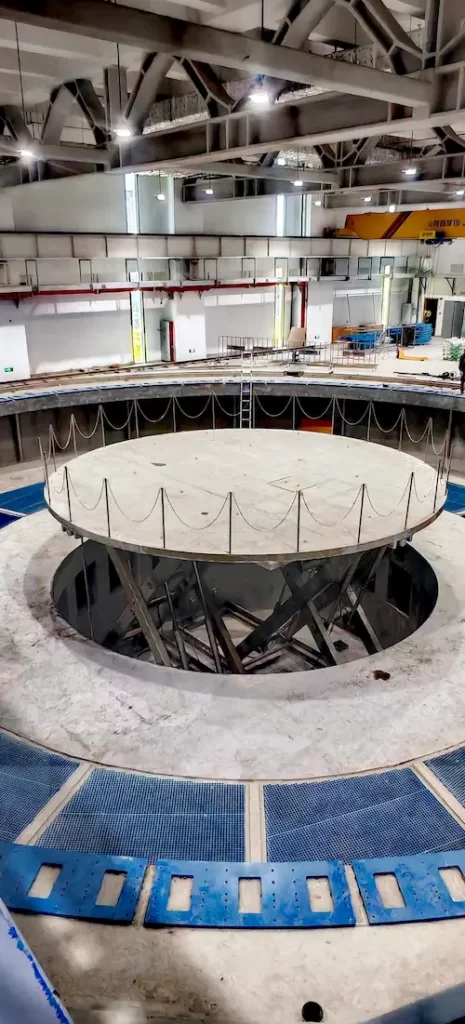

Olló típusú 316L rozsdamentes acélból készült víz alatti emelőplatform

POSTED: 12/31/2024

Használat

Used for Installing Rock Models and Experimental Equipment, the Platform Elevates to Simulate Testing Requirements Under Different Water Depth Conditions

Requirements

Structure and Material

- Hydraulic drive system, double-span single-layer structure.

- 316L stainless steel material, diameter 10 meters (to be adjusted based on site conditions).

- Lifting stroke ≥ 5.3 meters, rated load ≥ 11 tons.

Control and Monitoring

- Equipped with on-site and remote control functions.

- The lifting platform control cabinet must include a dehumidification and anti-salt control device.

- Set up underwater pull wire sensors (at least 2) to monitor lifting height, with positioning accuracy error ≤ ±5 mm.

Biztonsági védelem

- Comprehensive safety protection features: emergency stop, overload protection, explosion protection, manual descent, phase loss protection.

- Mechanical fall protection device, using hydraulic telescopic supports, quantity ≥ 4.

Performance Requirements

- Lifting speed ≥ 0.4 m/min.

- Hydraulic control must include a check valve.

- Hydraulic cylinders utilize double-layer sealing rings.

- The lifting platform surface uniformly distributed load ≥ 1 t/m².

- Overall flatness error ±5 mm.

Design Details

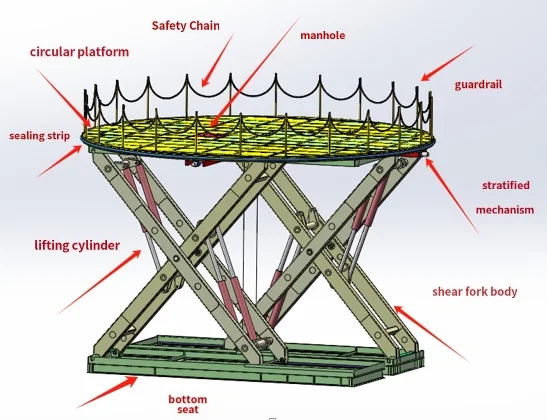

The edge of the platform features removable guardrails (21 in total), spaced 1.5 meters apart, connected by a middle chain, made of 316L stainless steel.

Surface panel thickness ≥ 6 mm, with tie-down rings.

Top surface pre-set with maintenance openings, and edge designed with sealed waterproof strips.

The top surface includes removable tie-down rings, which should not exceed the surface height when removed.

Solution

Ez az emelőplatform 316L rozsdamentes acélból készült ollós kialakítású, kifejezetten víz alatti használatra készült. Az ollós mechanikai szerkezetnek köszönhetően nagy stabilitást és teherbírást biztosít. A platform emellett érintőképernyős vezérlőrendszerrel van felszerelve, amely lehetővé teszi a felhasználók számára a célmagasságok beállítását és az aktuális magasság valós idejű megjelenítését.

Equipment Structure

The equipment mainly consists of:

- Lifting platform body

- Lifting platform accessories

- Hydraulic station

- Vezérlőrendszer

Hydraulic Pump Station

Provides power for the lifting equipment.

Vezérlőrendszer

Controls the operation of the equipment.

Lifting Platform Body

The lifting platform body consists of:

- Base

- Scissor mechanism

- Lifting cylinders

- Leveling lock pin mechanism

- Guiding mechanism

1. Base

Used to secure the equipment, the base is fixed to the foundation. Once the equipment is adjusted, the base is welded to the pre-embedded steel plates in the foundation, ensuring stability.

2. Scissor Mechanism

Transmits power and provides support for the equipment.

3. Upper Frame

Composed of a frame and a 6mm panel, it serves a load-bearing function. The surface is equipped with tie-down rings and maintenance openings as required.

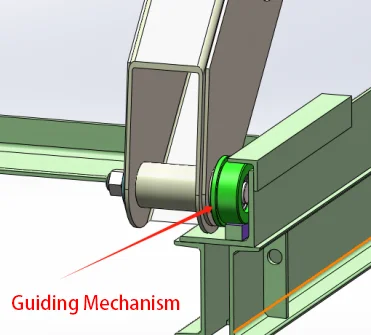

4. Guiding Mechanism

Comprises four sets of guiding wheel assemblies to enhance the stability of the equipment during lifting.

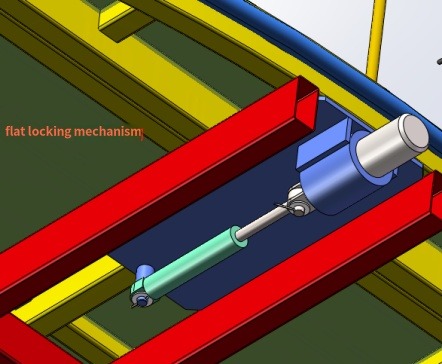

5. Leveling Lock Pin Mechanism

When the equipment is in a long-term working position, four sets of leveling lock pins extend into pre-fabricated holes under the action of the cylinders, ensuring positional accuracy and stability over time.

As shown in the diagram, the leveling lock pin mechanism includes cylinders, pin shafts, and fixed plates, welded underneath the circular platform to maintain its position without lowering.

6. Synchronization Mechanism

This equipment consists of a two-span structure with an integrated platform. The hydraulic system employs synchronous motors to maintain synchronization accuracy effectively.

The pump station directs oil to the synchronous motor, which then distributes oil through outlets A and B to the two sets of scissor cylinders, ensuring equal oil flow to both sides for stable lifting and synchronization of the scissor mechanisms.

Basic Parameters

| Termékmodell | SJG11-5.0 |

|---|---|

| Lifting Platform Size | D = 10000mm |

| Structure Type | Double-span single-layer |

| Dokkolóállomások | 2/2 |

| Stroke Range | ≥ 5000mm (1350-6500) |

| Névleges terhelés | 11000kg |

| Equipment Weight | Approximately 32 tons |

| Equipment Height | 1350mm (including raised frame) |

| Emelési sebesség | 0.4m/min |

| Telepítési módszer | Beágyazott alapítvány telepítése |

Ha testre szeretné szabni anyagmozgató berendezését, kérjük, hogy kapcsolatfelvétel.