CENTRE DE RESSOURCES > ÉTUDES DE CAS

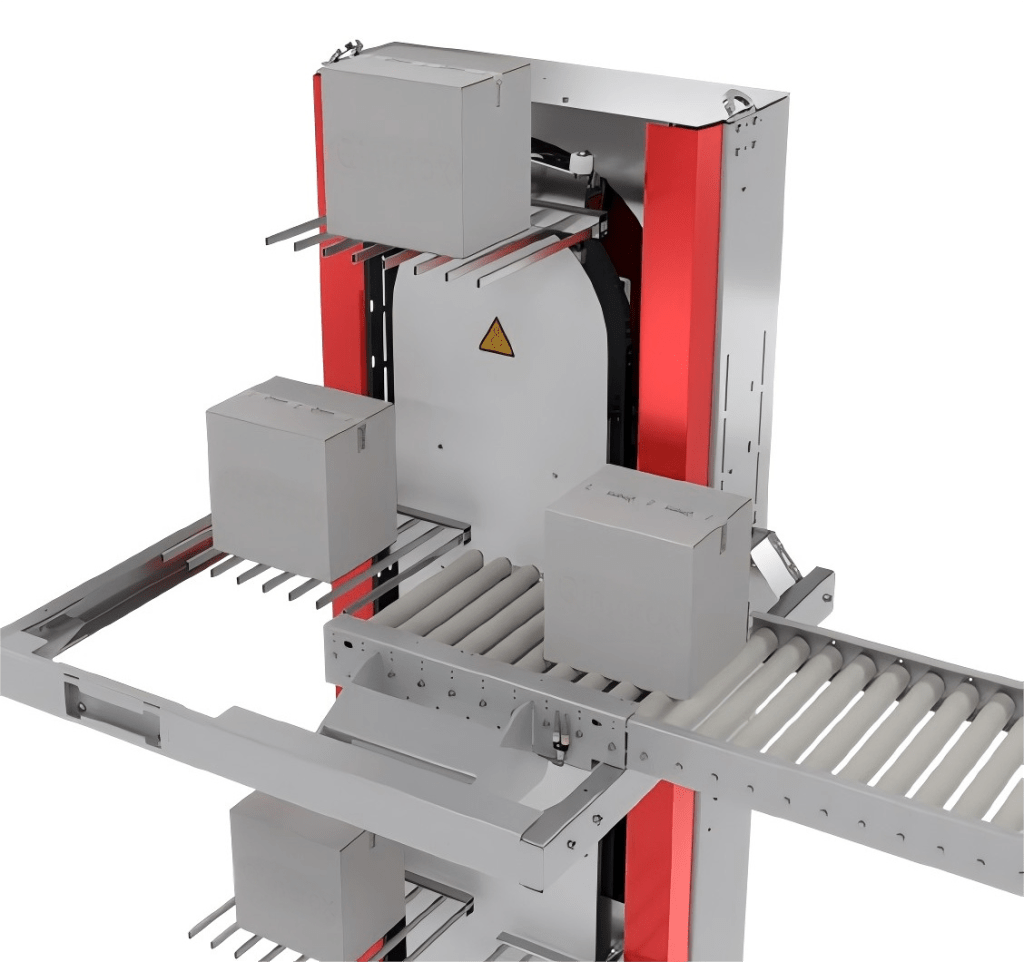

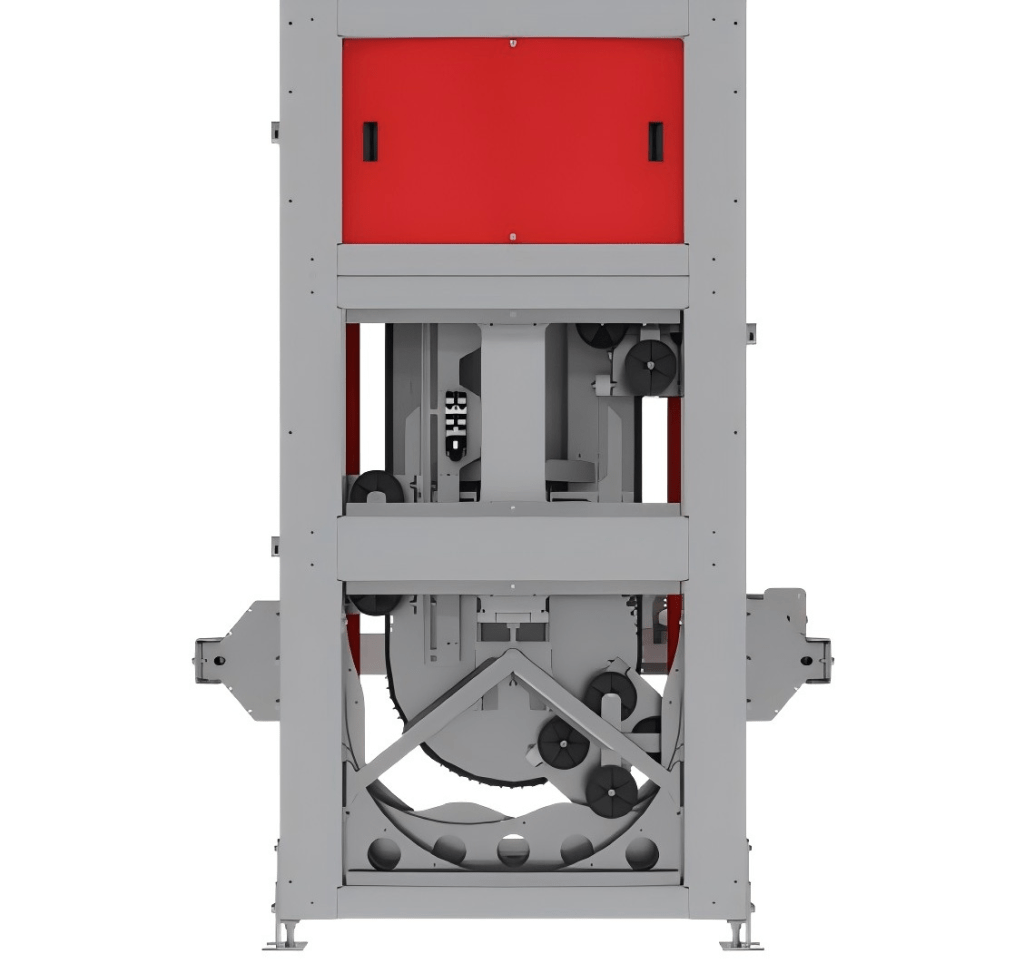

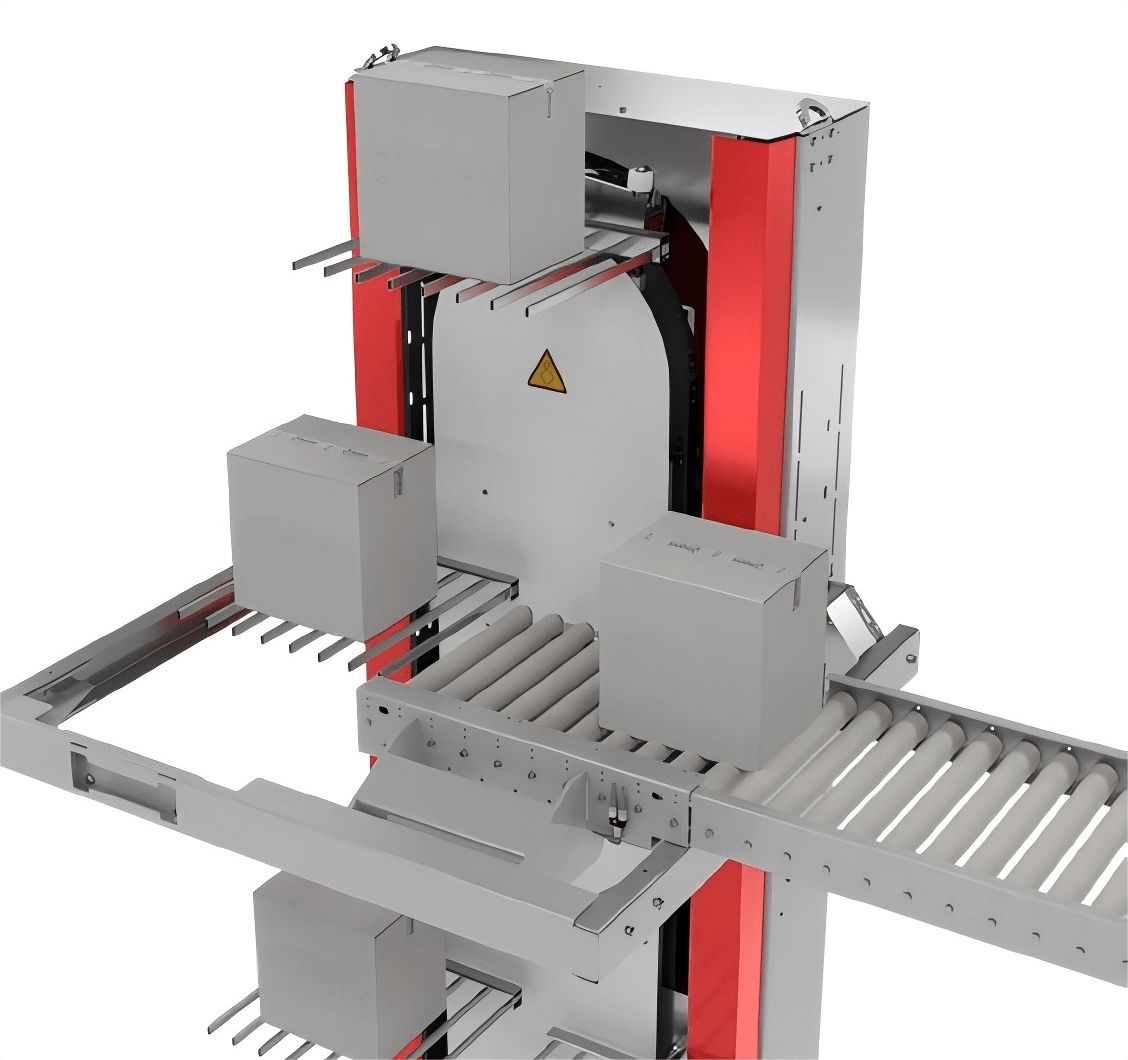

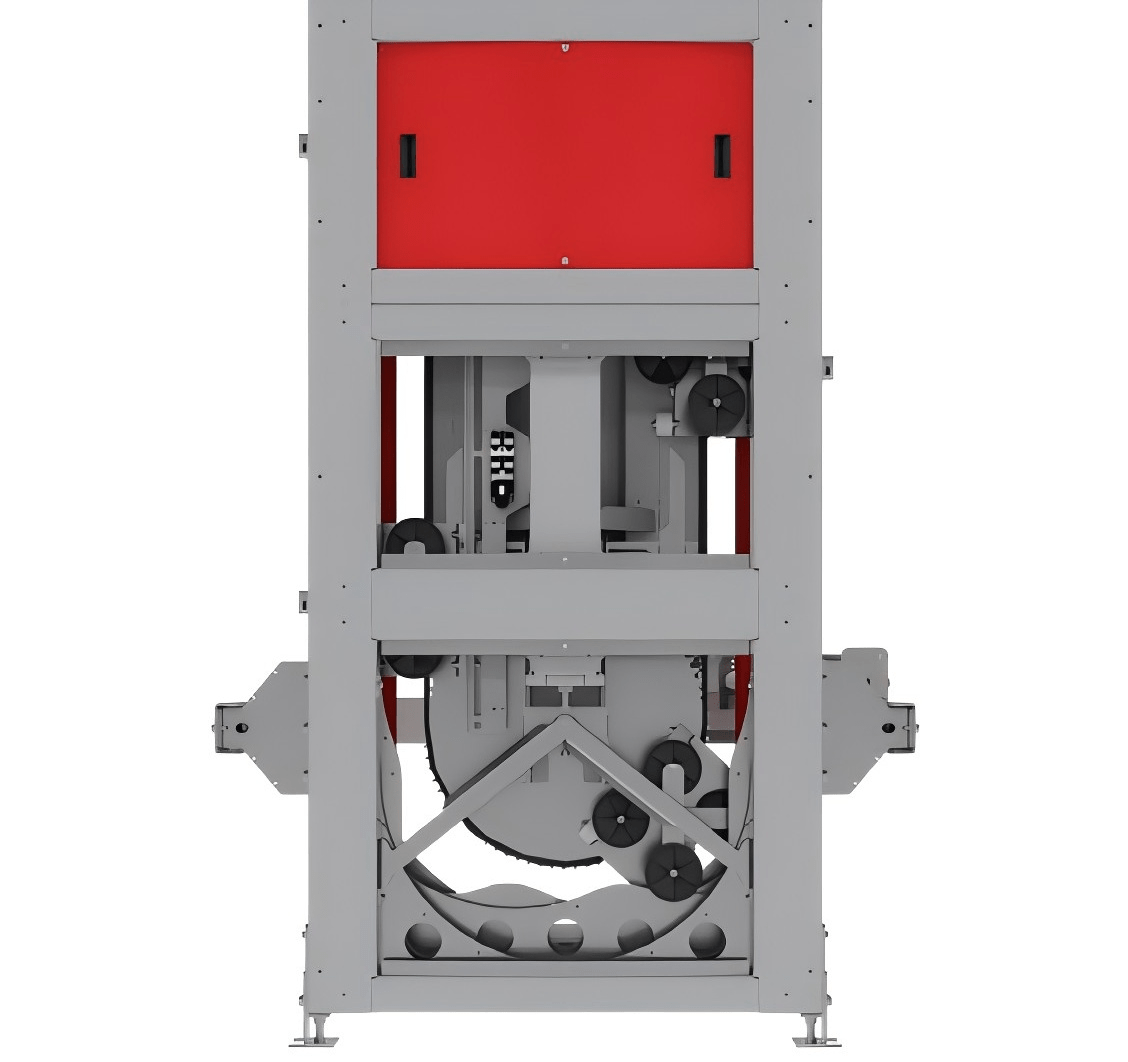

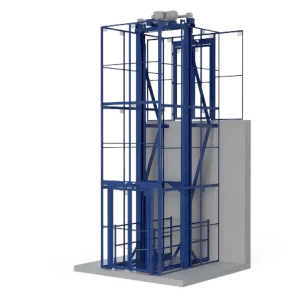

Élévateur vertical continu modulaire à bras de fourche | Convoyeur vertical 2000 unités/heure | Système de tri multi-matériaux

POSTED: 11/10/2025

Overview

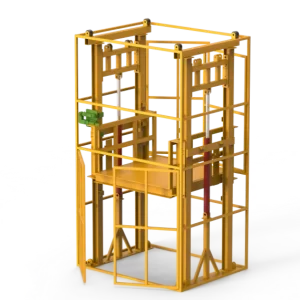

Le Modular Fork-Arm Continuous Vertical Lift is a cost-effective vertical conveyance solution specifically engineered for medium to high capacity scenarios.

Featuring an innovative modular structure, this equipment demonstrates exceptional performance in installation flexibility and transportation economy, while delivering a powerful handling capacity of 2000 units per hour.

Its unique fork-arm design ensures products remain upright throughout the conveyance process, effectively preventing material tilting and damage, and integrates bidirectional conveyance and vertical sorting functions to meet the extreme demands of modern logistics systems for space utilization and operational efficiency.

Solution

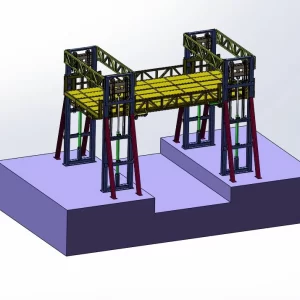

| Paramètres | Standard Type | Heavy-Duty Type |

|---|---|---|

| Inlet/Outlet Configuration | Single-in-single-out/Single-in-multiple-out/ Multiple-in-single-out/Multiple-in-multiple-out | Single-in-single-out/Single-in-multiple-out/ Multiple-in-single-out/Multiple-in-multiple-out |

| Minimum Inlet Height | 750mm | 750mm |

| Hauteur de levage maximale | 35 meters | 20 meters |

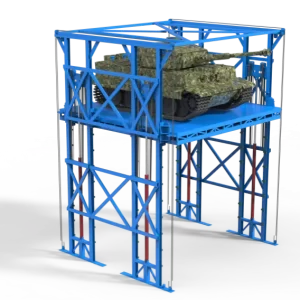

| Product Size | 600×400×500mm | 800×600×600mm |

| Capacité de charge nominale | 50 kg | 80kg |

| Conveyance Efficiency | 500-1500 units/hour | 500-1000 units/hour |

| Main Material | Painted Carbon Steel/Stainless Steel | Painted Carbon Steel/Stainless Steel |

Avantages

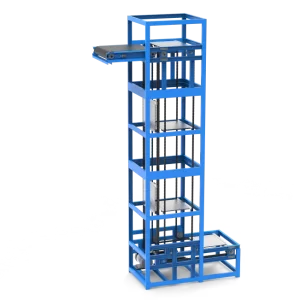

1. Superior Modular Design

- Prefabricated modular components significantly reduce installation time

- Flexible adaptation to various site space constraints

- Substantially lower transportation and installation costs

2. High-Efficiency Conveyance Performance

- Continuous cyclic operation without start-stop intervals

- Maximum handling capacity of 2000 units/hour

- Capacity increase achievable by adding tray quantities

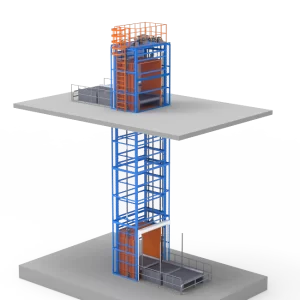

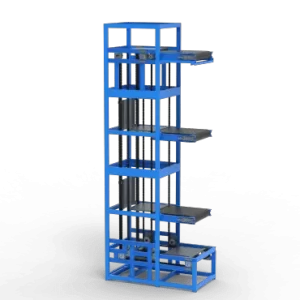

3. Flexible Infeed/Discharge Configuration

- Supports linear and vertical direction material flow

- Enables complex processes like single-in-multiple-out

- Flexible material distribution across multiple floors

4. Reliable Product Protection

- Fork-arm design ensures upright product conveyance

- Prevents damage caused by product tilting or collapsing

- Suitable for various fragile product types

5. Multi-Functional Application

- Combines vertical conveyance and sorting functions

- Optional motorized or gravity drive methods

- Supports bidirectional material flow

Industry Applications

- Order sorting in e-commerce logistics centers

- Inter-floor material handling in manufacturing

- Printed matter distribution systems in publishing

- Automated production lines in food and beverage

- Sorting centers in express parcel distribution

Produits CVC apparentés

Autres cas de CVC

Si vous souhaitez personnaliser votre équipement de manutention, veuillez cliquer ici. nous contacter.