RESOURCE CENTER > CASE STUDIES

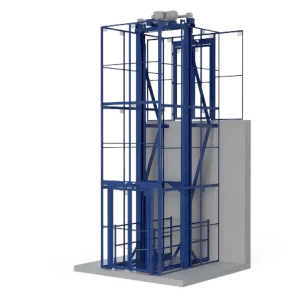

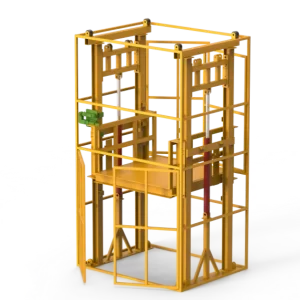

Reciprocating Lift Designed for Transporting Cat Litter

POSTED: 3/12/2024

Introduction

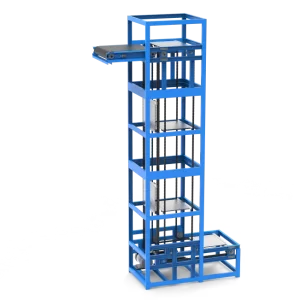

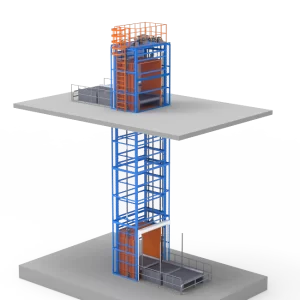

This reciprocating lift is specifically designed for transporting cat litter, combining efficient handling with intelligent packaging. The equipment has a maximum load capacity of 1500 kg and a lifting height of 16.5 meters. It supports multi-point transportation with three layers and three stations, achieving a running speed of up to 40 meters per minute.

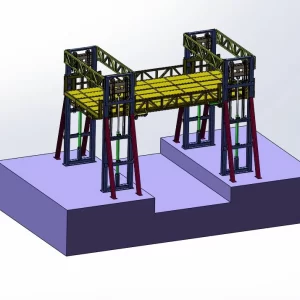

The accompanying automatic wrapping machine is integrated with the lift, allowing for automatic wrapping and packaging of goods after lifting, which enhances packaging efficiency and reduces manual labor. The device is built with a sturdy and durable structure, and its intelligent control makes operation simple and user-friendly. It can seamlessly connect with production lines, making it an ideal choice for cat litter manufacturing and logistics companies aiming to achieve automated operations.

Our Solution

| Item | Description |

|---|---|

| Product Name | Reciprocating Lift |

| Installation Location | From the first floor to the third floor (3 units, indoor) |

| Lift Structure | E-Type |

| Drive System | Energy-saving main motor |

| Control System | PLC variable frequency control (vertical lift), touch screen control |

| Rated Load Capacity | 1500 kg |

| Lifting Speed | 40 mm/min |

| Motor Power | 15 kW |

| Number of Stops | 3 stops (3 layers) |

| Lifting Height | 16500 mm (first layer 6500 mm, second layer 10000 mm) |

| Top Floor Height | 6500 mm for three layers, meeting installation dimensions |

| Pit Depth | 0 mm |

| Installation Dimensions | W2700 * L2500 mm |

| Cabin Dimensions | W1800 * L1800 mm |

| External Roller Dimensions | W1500 * L1600 mm |

| Cargo Dimensions | W1400 * L1400 * H2000 (including pallet) |

| Handling Method | Roller line connection, manual forklift loading and unloading |

| Horizontal Speed | 0~20 m/min (0.4 m/s), variable frequency |

| Cabin Space Dimensions | W1800 * L1800 * H2500 mm |

| Cabin Configuration | Equipped with roller conveyor table |

| Buffer | Polyurethane buffer |

| Safety Mechanism | Safety clamp + speed limiter linkage mechanism |

| Limit Switch | Limit switches at top and bottom |

| Positioning Method | Photoelectric positioning |

| Cargo Detection | Infrared detection |

| Leveling Control | Precise leveling sensors at each layer |

| Guide Rail | Elevator-specific guide rail |

| Equipment Acceptance | Standard gray (customizable) |

| Design Lifespan | 15 years |

| Installation Method | Shaft/opening in floor, indoor installation |

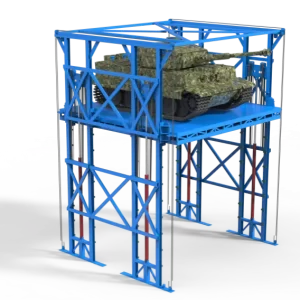

Related Products

If you want to customize your material handling equipment, please contact us.