RESOURCE CENTER > CASE STUDIES

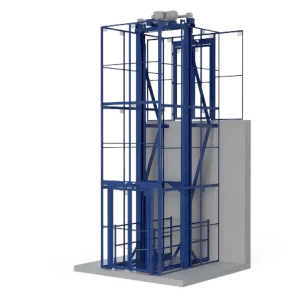

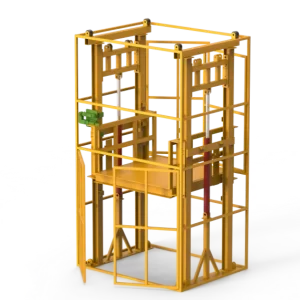

Automated Goods Lift for Unmanned Warehouses

POSTED: 11/13/2024

User

Fire Brigade Headquarters

Project Introduction

This goods lift is designed for integration with Automated Guided Vehicles (AGVs) in unmanned warehouses, enabling efficient transportation of goods.

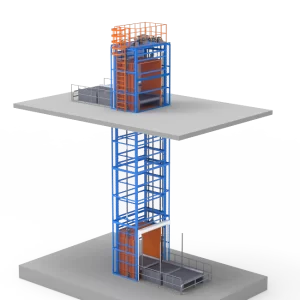

- AGV Operation: The AGV automatically retrieves goods and, after loading, navigates directly into the lift.

- Fully Automated Process: Once the AGV enters, the lift door automatically closes, facilitating transport without any human intervention. Operators can manage the system from their office, allowing them to retrieve goods and send them to the loading dock seamlessly.

- Cabin and Fast PVC Door: The lift is equipped with a cabin and a quick-acting PVC door to enhance operational efficiency.

- Communication Protocol: The system operates on a communication protocol. When the AGV arrives, it sends a signal to the lift platform to open the door. After the AGV enters, it sends another signal to close the door. Once the door is closed, the AGV receives a signal to initiate the lifting process, ensuring synchronized operation between the AGV and the lift.

This automated solution significantly enhances the efficiency of warehouse operations, allowing for streamlined goods handling without the need for manual labor.

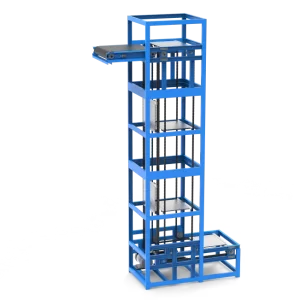

Lift Specifications

| Product Model | SJD2-15 |

| Platform Size (mm) | 2000 x 1500 x 2200 |

| Required Space Size (mm) | According to pit drawing |

| Docking Stations | 3 stations, 3 stops |

| Maximum Lifting Height (m) | 10 |

| Minimum Height of Lifting Platform (mm) | 120 (flush with ground when installed in pit) |

| Pit Depth (mm) | 200 |

| Entry/Exit Method | |

| Lifting Speed | 4-6 m/min |

| Maximum Load Capacity (kg) | 2000 |

| Power Supply | 380V / AC / 50Hz |

| Hydraulic Unit | Original product from Zhongding, complete hydraulic system |

| Drive System | Hydraulic drive |

| Operation Method | Digital button control, automatic stop at designated floors |

| Overload Protection | Overcurrent relay control |

| Finish Color | Mid-gray or blue |

| Operating Environment | Suitable for indoor and outdoor use |

| Operating Temperature | -20°C to 60°C |

| Installation Method | Shaft installation |

| External Control Device | 1) Automatic control 2) External control box installed near upper and lower stop levels; no control box on the platform |

| Emergency Stop | Pressing the emergency switch can control machine operation. |

| Manual Operation | Manual hydraulic valve can be opened or platform can descend manually by rotating the screw. |

Safety Features

| Feature | Description |

|---|---|

| Emergency Protection | Equipped with an emergency stop function to ensure the device does not cause secondary accidents in case of unexpected situations during operation. |

| Overload Protection | The power system (pump station) features an overload self-locking function. If the load exceeds the rated capacity, the self-locking function activates, preventing the device from rising to avoid accidents caused by excessive loading. |

| Emergency Descent | Manual descent device available in the event of power loss or malfunction. |

| Cylinder Protection | A locking device at the bottom of the hydraulic cylinder engages if the hydraulic hose breaks during operation, preventing rapid descent of the cylinder. |

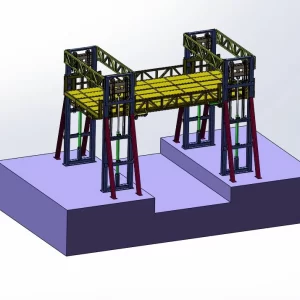

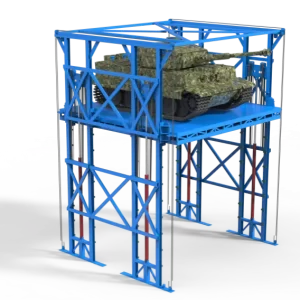

Related Freight Lift Products

Other Freight Lift Cases

If you want to customize your material handling equipment, please contact us.