Circulating Vertical Conveyors

Home > Vertical Lifts > Circulating Vertical Conveyors

Product Catalog

SOLUTIONS BY APPLICATION

WHAT’S YOUR APPLICATION?

Our design library and our engineering capabilities allow us to meet your application challenges. No matter what your challenge is, we’ll build the perfect lift you need.

SOLUTIONS BY INDUSTRY

WHAT’S YOUR INDUSTRY?

We understand industry-specific challenges better than anyone. From aerospace to retail, we are uniquely qualified to understand all of your challenges.

4 Posts (1) Articulating Staircase (1) Automated (2) Automation (1) Battery Electric (2) Boom Lift (4) Compact Design (1) Diesel (1) Double Chain (1) Durability (2) Easy to use (1) Efficient Actuation (1) Explosion-Proof (1) Fast Installation (1) Fixed (3) Guide Rail (3) Heavy Duty (3) High-Strength (4) Hydraulic (20) Hydraulic Iris Opening (1) Industrial Elevators (1) inspect (2) Logistics Equipment (1) Logistics Solutions (1) Maintenance Friendly (1) MEZZANINE (1) Mobile (1) Modular Design (2) Outdoor Lift (1) Production Line Solutions (1) Rigid Chain (1) Roller Chains (2) Safety (5) scissor lift (9) Self Propelled (3) Semi-Auto (1) Small (3) Stainless (1) Track-Mounted (1) Tracked (1) Vertical Lift (1) Vertical Transport (1) VRC (1) Warehouse Solutions (2) Weather Resistance (1)

What are Circulating Vertical Conveyors

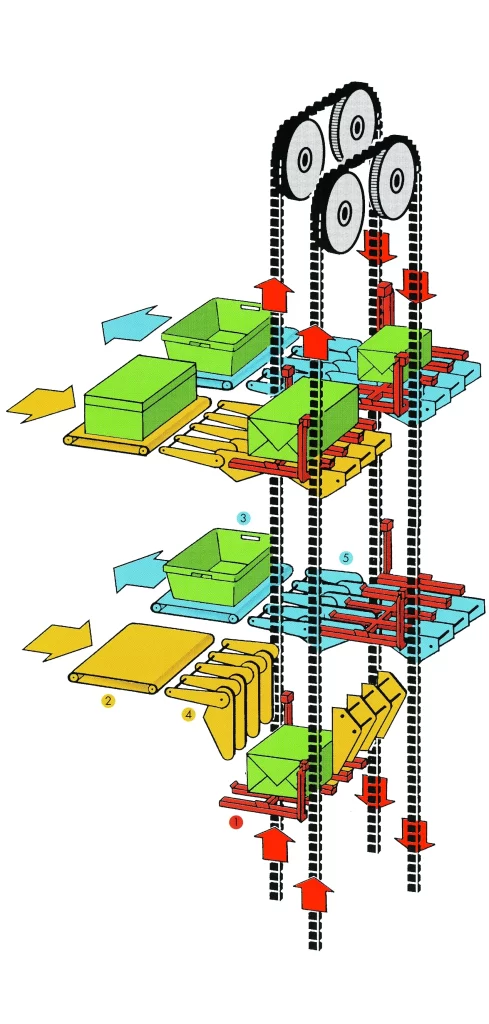

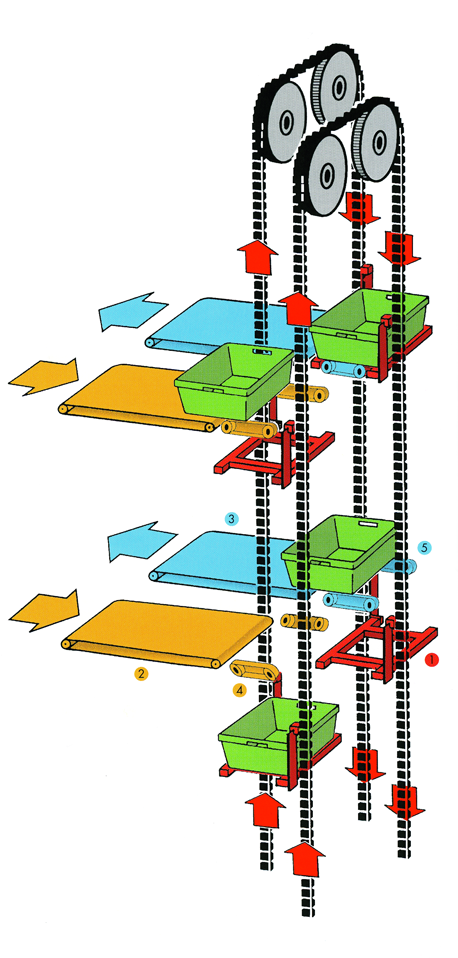

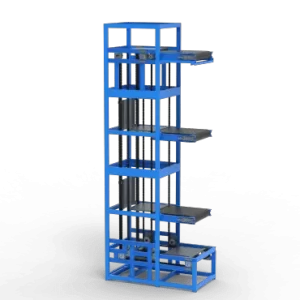

The CycleLift Pro 400 is a continuous vertical conveyor that offers an unexpectedly low price compared to traditional discontinuous conveyors. This modular system can achieve a throughput of up to 2,200 products per hour, making it highly efficient for material handling.

Circulating Vertical Conveyors are available in two models:

Key Features

- Modular Design: The Prorunner CycleLift Pro 400‘s modular setup allows for smaller shipment volumes, reducing shipping costs.

- Versatile Applications: It can transport a wide range of products, including boxes, cases, trays, and bags, effortlessly and quickly between different floors.

- Energy Efficiency: Designed to minimize energy consumption while maximizing throughput, making it an environmentally friendly option.

- Upright Positioning: Products are always carried upright, eliminating the risk of deformation during transport.

This makes the Prorunner CycleLift Pro 400 ideal for businesses looking to enhance their material handling processes while maintaining cost-effectiveness and product integrity.

Specifications

- Lowest Infeed/Outfeed Position: 700 mm / 27.6 inches

- Highest Infeed/Outfeed Position: 19,500 mm / 767 inches

- Maximum Column Height: 20,000 mm / 65.6 feet

- Drive System: SEW 0.37 kW

- Maximum Product Weight: 55 kg per carrier / 121 lbs per carrier

- Minimum Product Size: 230 mm x W x 50 mm / 9.1 inches x W x 2 inches

- Maximum Product Size: 610 mm x 620 mm x H / 24 inches x 24.4 inches x H

- Throughput: 1 carrier for 220 products per hour (additional carriers can be added for higher capacities)

- Configuration: B3 or C2 for elevating; 6G or 7F for descending (more options available with different carrier types)

- Securyfence Safety Fencing Height: 2150 mm / 84.6 inches

- Pitch of Product Carrier: 80 mm / 3.15 inches

- Infeed Conveyor: Gravity roller conveyor / powered roller conveyor (optional)

- Outfeed Conveyor: Gravity roller conveyor / powered roller conveyor (optional)

Conveyor Sections

Carriers

Carriers are fork-type platforms that transport products. They are connected to two Rubber Block Chains, ensuring smooth and stable movement throughout the conveyor.

Rubber Block Chains

GRADIN’s Rubber Block Chains have high-tensile steel cables inside, allowing for lubrication- and maintenance-free operation. This design provides quiet and clean long-term performance. Different rubber compounds are available for various environments.

Retractable Feed Conveyors

These conveyors feed material on the upward side and discharge it on the downward side, ensuring a clean transfer from horizontal to vertical transport. The feed conveyor starts and stops automatically as needed.

Casings

Casings are available in welded painted carbon steel or stainless steel frames. Carbon steel options can be powder-coated or painted for durability and easy cleaning.

Cladding

Cladding can be made from perforated aluminum or steel sheets, protecting both the conveyor and products while ensuring a safe work environment.

Maintenance Features

All GRADIN circulating vertical conveyors have large servicing and monitoring openings and removable covers for easy maintenance.

This design makes GRADIN vertical conveyors efficient, safe, and easy to maintain, suitable for various material handling applications.

Why choose Gradin?

Established in 2000, Jinan Gradin Machinery Co., Ltd. is a renowned manufacturer specializing in customized and standard lift solutions to meet a wide range of requirements.

Our state-of-the-art production facility spans an impressive 60,000 square meters, encompassing assembling workshops, structural workshops, paint workshops, final product test fields, hydraulic and electric laboratories, an R&D center, an administration center, and staff accommodations. This extensive infrastructure enables us to maintain the highest standards of manufacturing excellence.

Committed to innovation and quality, we have collaborated with multiple domestic machinery institutes and hold more than 60 patents. Our products have received certifications from both domestic and international regulatory bodies, including the Special Equipment Production License, Special Equipment Installation Modification License, ISO9001, CE, AS/NZS1418, CU-TR, and KC.

Top Rated Products

-

E-shaped Vertical Reciprocating Conveyors Lift

-

4 Posts Fully-caged Cargo Lift

-

4 Posts Mezzanine Goods Lift

-

2 Posts Wall-mounted Cargo Lift

-

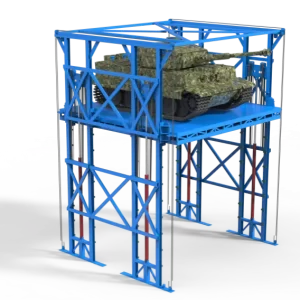

8 Posts Cargo Lift